Preparing a cement plant for carbon capture

While a range of post-combustion carbon capture technologies are now receiving interest from the ...

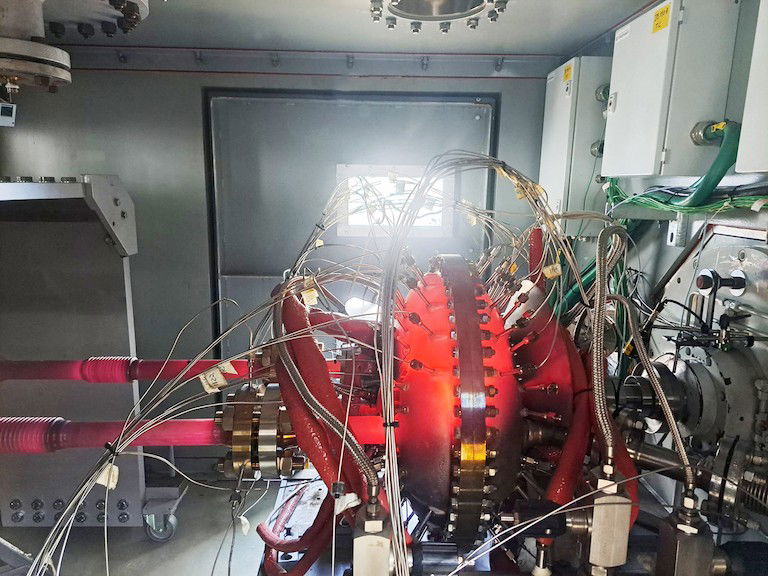

Electric kilns are quickly advancing from laboratory testing to pilot projects, bringing with them the tantalising possibility of large-scale emissions reduction for the cement industry. Emerging solutions such as Coolbrook's RotoDynamic Heater™ show that it does not need to be a choice between sustainability and performance. By Joonas Rauramo, Coolbrook, Finland

GBP£220 / USD$315 / EUR€260 annually

Our editors pick the top news delivered to your inbox. Sign-up today!